Handmade in the uk

Handmade in the uk

Aston Martin DB2 Engine Bay Light Assembly

New- DB2 First Sanction

- DB2

- DB2/4 MK I

- DB2/4 MK II

- DB MK III

Period‑correct, handmade aluminium DB2 engine bay light assemblies are designed to mount directly to the underside of the bonnet using the existing threaded studs from the centre bonnet moulding. These assemblies provide a practical lighting solution for the engine compartment when the bonnet is open.

Each assembly features a hand‑formed aluminium housing and mounting bracket, complete with fitted bulb, rubber bulb housing, integrated switch, and period‑style braided wiring. The switch is positioned on the side of the metal housing replicating the original configuration.

Our mounting bracket incorporates a single pre‑drilled hole, allowing customers to position and align over one protruding stud before marking and drilling the second mounting point to match the second stud. This simple, flexible approach accommodates the likely variations in existing stud positioning.

Customers may select between polished or fine brushed aluminium finishes to suit their restoration preferences and intended use. Polished aluminium is relatively easy to clean, authentic and does not need to be painted. Having said that, many genuine housings were painted to match the colour of the bonnet, in which case, the brushed version is better suited.

Available separately are our engine bay air inlet frame and gauze assemblies that also mount to the underside of the bonnet.

Our brushed aluminium engine bay light housings feature a fine, consistent brush finish that provides an ideal foundation for painting to match vehicle colour schemes. The aluminium mounting bracket strip is also a natural brush finish. This part is not chrome plated.

Primarily made‑to‑order production.

No additional fasteners are supplied—customers utilise existing centre bonnet moulding studs and for correct and secure mounting.

Customers should be aware that vehicles with extensive repairs may have altered bodywork geometry due to paintwork processes and body filler usage, which can subtly affect panel shape where components are positioned. DMark® has taken considerable care to replicate the most authentic original geometry, though this may occasionally differ from a vehicle’s current surface characteristics. Similarly, stud hole positions in bodywork may vary from new DMark® component specifications and minor adjustments may occasionally be required to achieve optimal fitment.

Complete engine bay light assembly comprising the handmade aluminium housing, mounting bracket strip, fitted bulb, rubber bulb housing, side‑mounted switch, and braided wire. The brushed finish is specifically suited for customers intending to paint the housing to match their vehicle’s bonnet colour.

Bracket Customisation

At DMark® we can position and drill holes on the mounting bracket specific to your vehicle’s centre moulding and bonnet stud spacings.

Required Information: Please provide stud centre distances, preferred mounting positions, or dimensional sketches to facilitate precise customisation.

We welcome various forms of specification data including detailed measurement mark‑up, annotated diagrams, hand‑drawn sketches, photographs, CAD drawings, or original factory documentation.

Bespoke by DMark®

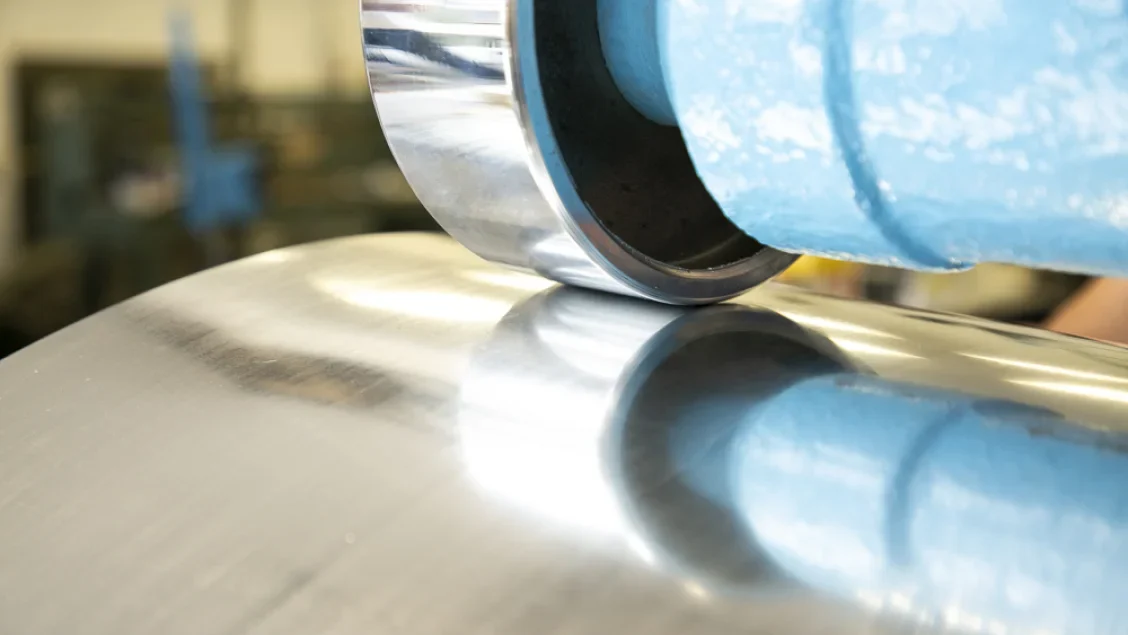

Our polished aluminium engine bay light housings are finished to a high lustre that requires no additional treatment. This authentic finish is relatively easy to maintain and clean, providing long‑term durability while preserving an authentic period appearance.

Complete engine bay light assembly featuring a polished aluminium housing designed to remain in its natural reflective finish. This variant provides an authentic period appearance while offering ease of maintenance.