Handmade in the uk

Handmade in the uk

Aston Martin DB2 Centre Bonnet Mouldings

- DB2 First Sanction

- DB2

- DB2/4 MK I

- DB2/4 MK II

- DB MK III

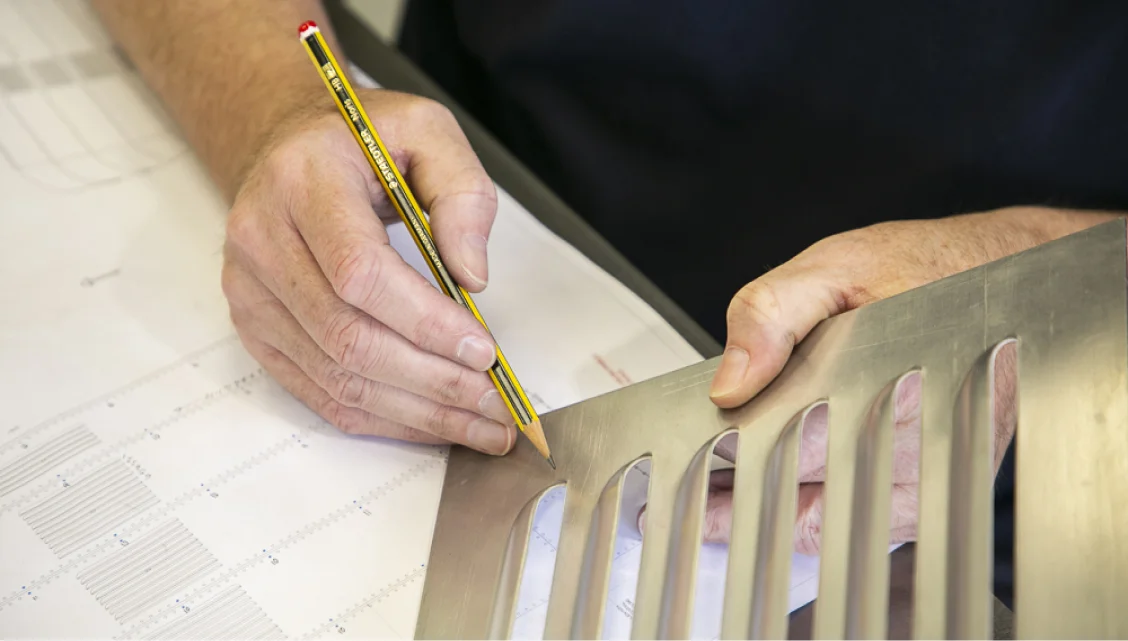

Handmade brass centre bonnet mouldings fitted along the centreline of all DB2 models, spanning from the Aston Martin badge above the grille to the air intake towards the windscreen. The triangular‑profiled moulding secures to the aluminium bonnet skin through a series of BA threaded studs that are soldered to the brass trim profile.

Every DMark® centre bonnet moulding’s cavity is filled with body‑solder—a crucial enhancement that stabilises and strengthens these inherently fragile, elongated components. This reinforcement significantly reduces the risk of deformation during installation, allowing the moulding to conform smoothly to the vehicle’s bodywork contours while maintaining structural integrity.

Through decades of experience manufacturing and restoring centre bonnet mouldings across the Feltham era DB2 range, we’ve identified distinct length variations between model types. Our comprehensive offering includes four fixed‑length variants designed to accommodate nearly all DB2 configurations.

When standard lengths prove unsuitable, we offer bespoke manufacturing to customer‑supplied specifications.

Entirely handmade using our proprietary DMark® custom tooling, jigs, patterns and manufacturing aids—all derived from original factory drawings and dimensional data gathered from authentic parts over many years.

All DMark® DB2 centre bonnet mouldings are finished as polished brass, meticulously prepared and chrome‑ready.

Customers may receive their new centre bonnet moulding in polished brass or chrome finish. DMark® partners exclusively with established, reputable electroplating specialists who share our exacting quality standards.

These centre bonnet mouldings are essentially bolt‑on components, so many clients prefer us to manage the chrome plating process. However, we understand that some customers prefer to handle plating themselves—particularly when coordinating comprehensive restoration work and batching chrome components together after dry‑fitting.

Primarily made‑to‑order, though we typically maintain raw materials in stock for prompt manufacturing.

Complete fixtures and fasteners (nuts and washers) are supplied with every moulding.

The internal triangle cavity is filled with body‑solder, providing essential structural stability. This reinforcement strengthens these traditionally fragile components into more robust brightwork better capable of withstanding external stresses.

Customers should be aware that vehicles with extensive repairs may have altered bodywork geometry due to paintwork processes and body filler usage, which can subtly affect panel shape where mouldings are positioned. We have taken considerable care to replicate the most authentic original geometry, though this may occasionally differ from a vehicle’s current surface characteristics. Similarly, stud hole positions in bodywork may vary from new DMark® component specifications and minor adjustments may occasionally be required to achieve optimal fitment.

Manufactured for various DB2 models, this variant features a consistent narrow profile with parallel sides and short tapers at both ends. Overall length measures 44 5⁄16″ tip‑to‑tip along the arc.

Designed for specific DB2 vehicles, this variant maintains the characteristic narrow parallel profile with subtle but short end tapers. Overall length measures 46 1⁄8″ tip‑to‑tip along the arc.

Suited to particular DB2 cars, featuring the traditional narrow parallel design with graduated but short end tapering. Overall length measures 46 3⁄4″ tip‑to‑tip along the arc.

Seen on the DB2/4 MK III models, though customers with different model types have also selected this distinctive style. This variant features a more pronounced profile—taller, more sculpted, and with enhanced tapering—creating a more substantial visual presence on the bonnet. Overall length measures 44 3⁄4″ tip‑to‑tip along the arc.

Bespoke Manufacture: Due to the wide range of centre bonnet moulding lengths we’ve encountered—reflecting what Aston Martin themselves produced throughout their DB2 production history—custom manufacture often provides the most precise solution. Sometimes it’s easier for customers to specify the exact type and length that matches their vehicle or original part being replaced.

Required Dimensions: Ideally we will want as many dimensions as possible, a good starting point would be measurements for;

- Tip‑to‑tip measurement (along arc)

- Tip‑to‑tip measurement (straight line)

- From rear stud‑to‑tip distance

- From front stud‑to‑tip distance

- Centre distance between studs

- Width at widest point

- Height at tallest point

Customisation

This variant accommodates specific dimensional requirements unique to individual vehicles.

We welcome various forms of specification data including detailed measurements, annotated diagrams, hand‑drawn sketches, photographs, CAD drawings, or even period factory documentation.

Bespoke by DMark®