Handmade in the uk

Handmade in the uk

Aston Martin DB MK III Door Waist Moulding

Coming soon- DB MK III

Coming soon — brass door waist mouldings that recreate the trim mounted to the upper edge of DB MK III doors. These identifying brightwork components form part of the continuous decorative trim line that flows from the door towards the rear quarter window, maintaining period‑correct authenticity for all MK III cars—concours‑standard and all other restorations.

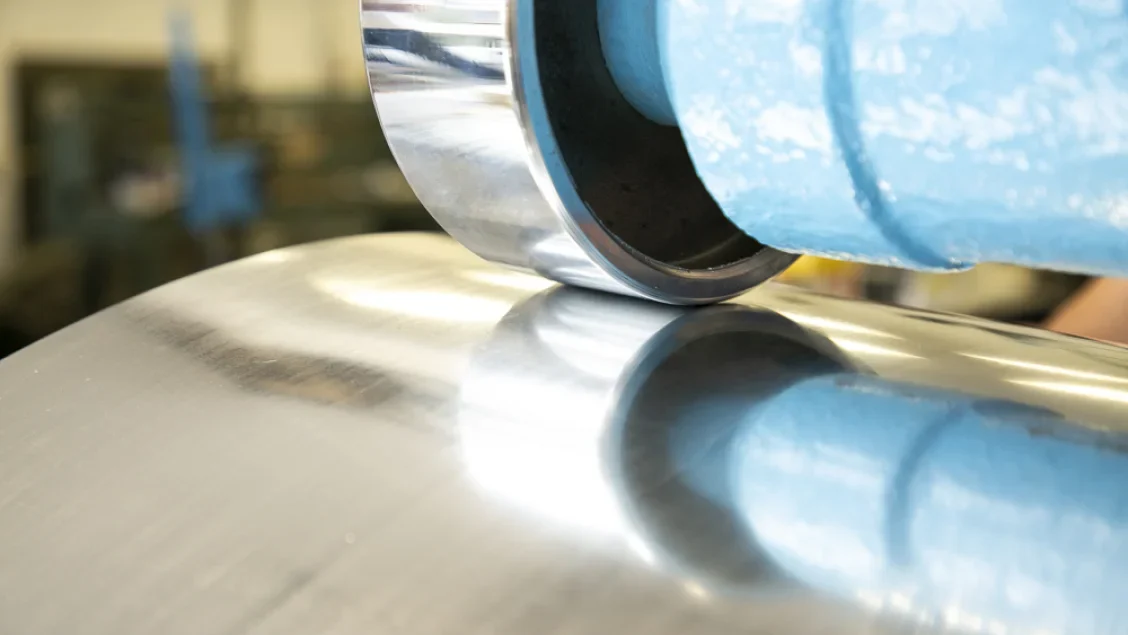

Each moulding features the distinctive half‑round profile with straight‑cut ends, manufactured using dimensional data sourced from original factory components. Fabricated using our new proprietary DMark® custom tooling, patterns and manufacturing aids—refined through decades of expertise in remanufacturing true Aston Martin DB2 series trim components.

At DMark® we have improved the original specification by addressing the mounting vulnerabilities commonly found in period components like these. While original door waist mouldings utilised BA threaded studs set in lead filler, our improved design strengthens that stud attachment, providing more reliable long‑term assurance and secure fitting.

Following 1950s manufacturing practices, the internal half‑round cavity is filled with body‑solder, delivering the same structural reinforcement we apply to our centre bonnet mouldings, stiffening these inherently delicate trim pieces into more robust brightwork components capable of withstanding both installation forces and decades of use.

These door waist mouldings align perfectly with our matching DB MK III Quarter Waist Mouldings, ensuring seamless visual continuity across the vehicle’s waist line trim.

All DMark® DB MK III door waist mouldings are finished as polished brass, meticulously prepared and chrome‑ready.

Customers may receive their new door waist mouldings in polished brass or chrome plated. DMark® partners exclusively with established, reputable electroplating specialists who share our exacting quality standards and understand the specific requirements of automotive brightwork.

DB MK III door waist mouldings are essentially bolt‑on components, so many clients prefer us to manage the chrome plating process for consistency and quality assurance. However, we understand that some customers prefer to coordinate plating themselves—particularly when preparing comprehensive restoration work and batching chrome components together following dry‑fitting.

Expected availability 2026.

Complete fixtures and fasteners (nuts and washers) are supplied with every moulding.

Handmade brass construction featuring a better BA threaded stud attachment approach. The internal half‑round cavity is filled with body‑solder for greater structural reinforcement.

Our standard stud positioning, derived from original factory components, accommodates the majority of vehicle mounting points. Hole positioning within panelling can vary from one vehicle to another, so for customers requiring specific stud placement to match unique bodywork characteristics, custom positioning can be arranged upon request with client‑supplied measurements.

Mouldings can be supplied at standard dimensions, cut to customer‑specified measurements, or manufactured oversized with additional material length for customer trimming and tailoring to their specific door. This approach accommodates any variations in door or window fitment or alignment for a close fitting trim.

Customers should be aware that vehicles with extensive repairs may have altered bodywork geometry due to paintwork processes and body filler usage, which can subtly affect panel shape where mouldings are positioned. We have taken considerable care to replicate the most authentic original geometry, though this may occasionally differ from a vehicle’s current surface characteristics. Similarly, stud hole positions in bodywork may vary from new DMark® component specifications, and minor adjustments may occasionally be required to achieve optimal fitment.

A pair comprising both near‑side and off‑side door waist mouldings for DB MK III models. Each moulding features that particular half‑round profile with straight‑cut ends, complete with stronger BA stud fixturing and mounting hardware for a reliable installation.

The most popular option for customers undertaking comprehensive restoration projects, concours preparation, or trim replacement where original trim mounting integrity has deteriorated over time.

Customers are encouraged to consider our matching DB MK III Quarter Waist Mouldings that mount beneath the rear quarter window, creating that continuous waist line trim presentation characteristic of the model.

Better Stud Fixture Strength

Every DMark® door waist moulding benefits from our comprehensive evaluation and improvement process—detailed analysis of original factory components followed by targeted engineering enhancements. Through examination of how these components were originally manufactured in the 1950s and observation of their performance over subsequent decades, we have identified the primary weakness: inadequate stud retention within the original lead filling.

Our solution increases the effective surface area of the stud connection within the body‑solder itself, creating a more secure bond that resists loosening, thread damage, and pull‑out failures commonly experienced with original components over time.

A Stiffer Reinforced Part

The internal half‑round profile is filled with body‑solder (replacing the lead‑based filler used in original 1950s production). This reinforcement provides sounder structural stability to these inherently vulnerable trim pieces, creating more resilient brightwork that better maintains its shape and integrity through polishing, chrome‑plating, installation and long‑term service.

Component Longevity & Replacement Considerations

While door waist mouldings typically survive better than other trim components, the passage of seven decades inevitably affects their mounting reliability and structural integrity. Most commonly, customers seek replacements when original threaded attachments have weakened to the point where secure reinstallation becomes impossible—a particular concern for vehicles undergoing restoration, concours preparation, or pre‑sale betterment where authenticity and presentation quality are paramount.

Our door waist mouldings represent the completion of the waist line trim detailing when combined with our quarter waist mouldings.

Near‑side door waist moulding only, for customers requiring single‑side replacement or phased restoration approaches.

Off‑side door waist moulding only, for customers requiring single‑side replacement or phased restoration approaches.